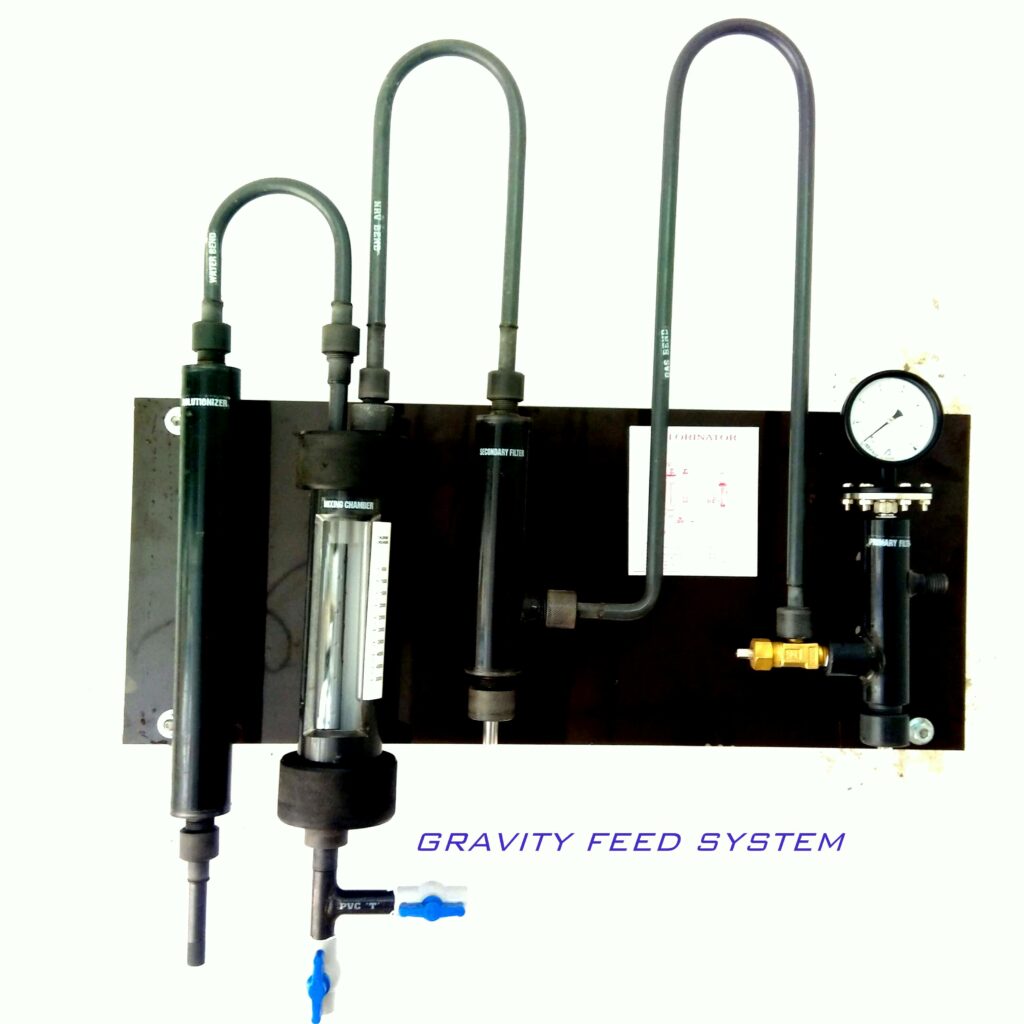

GRAVITY FEED CHLORINATION SYSTEM

Gravity feeds chlorination system ensures continuous and constant flow of chlorine gas through gravity supply of water. It is made up of selected rigid PVC material. These do not react with chlorine gas and is non corrosive. Gravity feed systems are easy to install and operate; the open design helps in easy maintenance and easy repairs with less operating cost. The capacity normally ranges from 0-10 kg/hr dozing.

Benefits of the Gravity System

- Safer – no leaks or spills

- Simple – nothing moves except the water

- Low capital costs – negligible by comparison

- Convenient – located right at the addition point

- Minimal training required

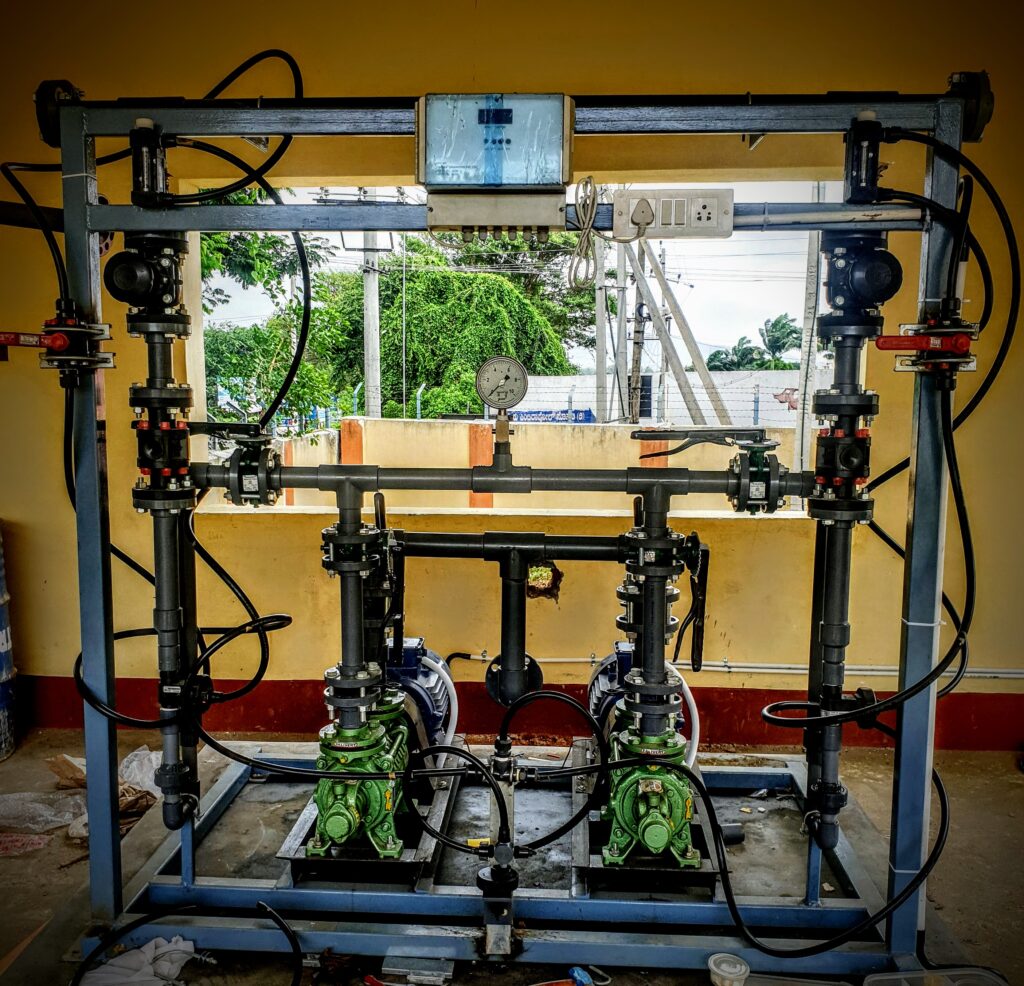

VACUUM FEED CHLORINATION SYSTEM

The principal use of the Vacuum feed Gas Chlorinator is to chlorinate water, wastewater and industrial process water with gas chlorine. The simple, efficient design has made vacuum feed Gas Chlorinators the industry standard. Built with heavy duty corrosion resistant parts, Chlorinators provide safe, long-lasting service.

The Chlorinator is a vacuum-operated, solution feed type, designed for mounting directly on a chlorine cylinder valve or for mounting on wall manifold or ton container adaptor. A chlorine gas flow meter panel indicates the amount of chlorine being fed and may be located wherever it is safest and most convenient. The chlorine flow rate is manually adjusted and is regulated by a spring opposed diaphragm regulator which also contains the safety shutoff valve. Vacuum is provided by highly efficient water operated ejector which is close coupled with the chlorine solution diffuser. The ejector assembly contains a back flow check valve.

ELECTRO CHLORINATION SYSTEM

Electro chlorination is the process of generating Sodium Hypochlorite (NaOCl) through the electrolysis of salt water. Sodium Hypochlorite is used to disinfect water. Electrochlorinator are a safer, lower cost and lower maintenance alternative to chlorine gas or bleach (both liquid and powder). Electrochlorination finds its applications in disinfection of drinking water, controlling biofouling in cooling towers, disinfection of ballast water in ships, fire water systems, large fountains, pools, water based amusement parks etc

CHLORINE TONNER/CYLINDER

Liquid chlorine is basically a greenish yellow liquefied chemical having a pungent odour. These cater to the requirements of various industrial applications such as water purification, disinfecting agent, bleaching agent, waste and sewage treatment and sanitizing. Due to the corrosive and toxic nature of the gas it has to be stored in appropriate tonners/cylinders of perfect specifications. These chlorine toner/cylinders shall be fabricated at par with industry standards to ensure easy usage and safe applications.

LEAK ABSORPTION SYSTEM

Chlorine Gas leak Detector is the process of identifying potentially hazardous gas leaks by sensors. These sensors usually employ an audible alarm to alert people when a dangerous gas has been detected.Chlorine Gas Leak Detector especially for toxic gases such as Chlorine & Combustible gases such as Ammonia. These detector monitors gas leaks for continuous operation in an open or confined are. It provides an audible alarm and visual indication of gas toxicity status. The sensor with alarm are easy to install are lightweight, self-contained and wall mounted.The chlorine gas leak sensor can be installed in field upto a distance of 100 meters

CHLORINE LEAK DETECTORS

Chlorine Gas leak Detector is the process of identifying potentially hazardous gas leaks by sensors. These sensors usually employ an audible alarm to alert people when a dangerous gas has been detected.Chlorine Gas Leak Detector especially for toxic gases such as Chlorine & Combustible gases such as Ammonia. These detector monitors gas leaks for continuous operation in an open or confined are. It provides an audible alarm and visual indication of gas toxicity status. The sensor with alarm are easy to install are lightweight, self-contained and wall mounted.The chlorine gas leak sensor can be installed in field upto a distance of 100 meters from monitors.